AI-driven robot-assisted system for non-destructive testing of composite structures

A platform connecting all stakeholders in construction boosting efficiency? It exists and it’s called DigiTrace.

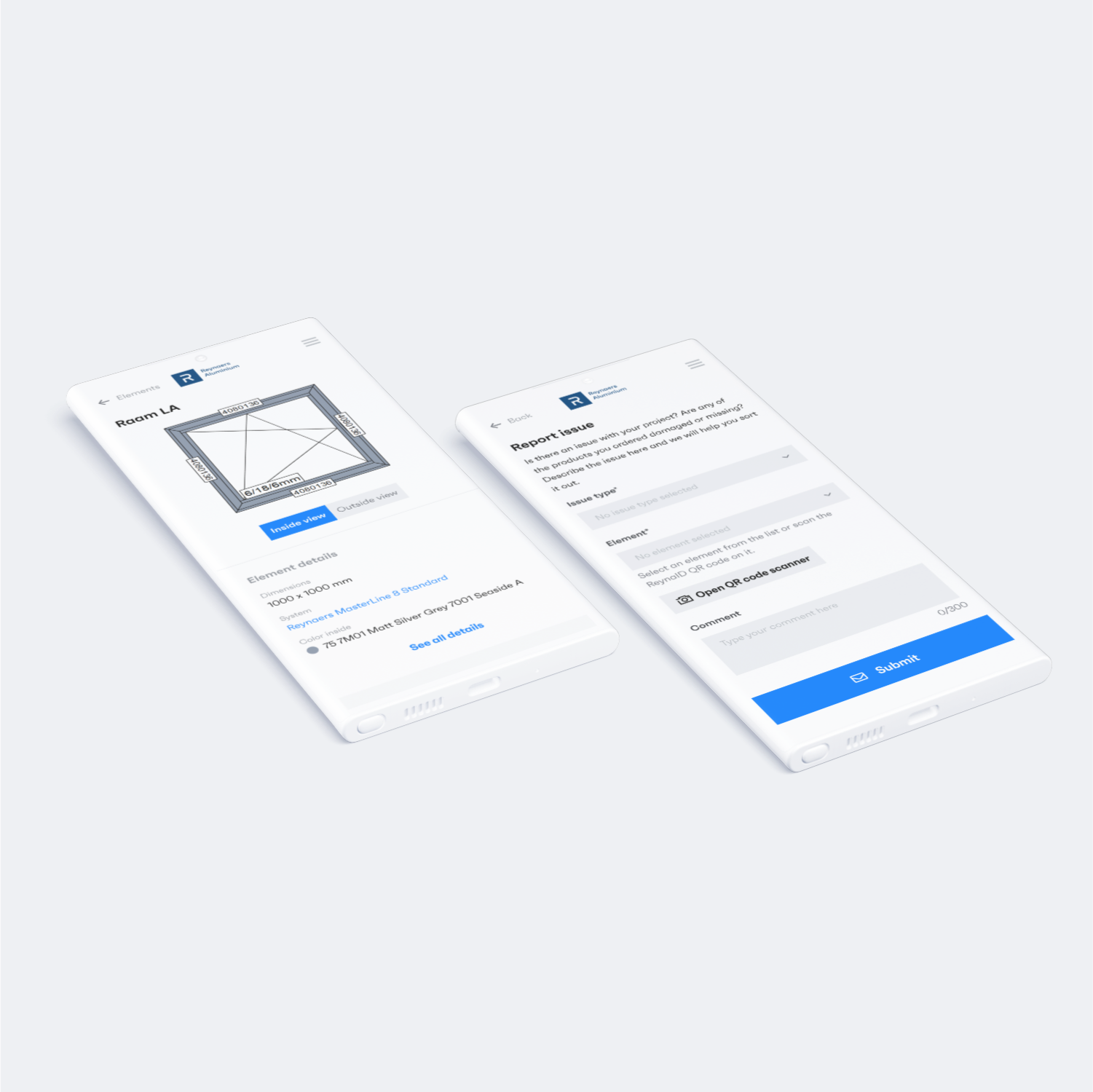

Reynaers DigiTrace

A little QR code building loyalty in construction

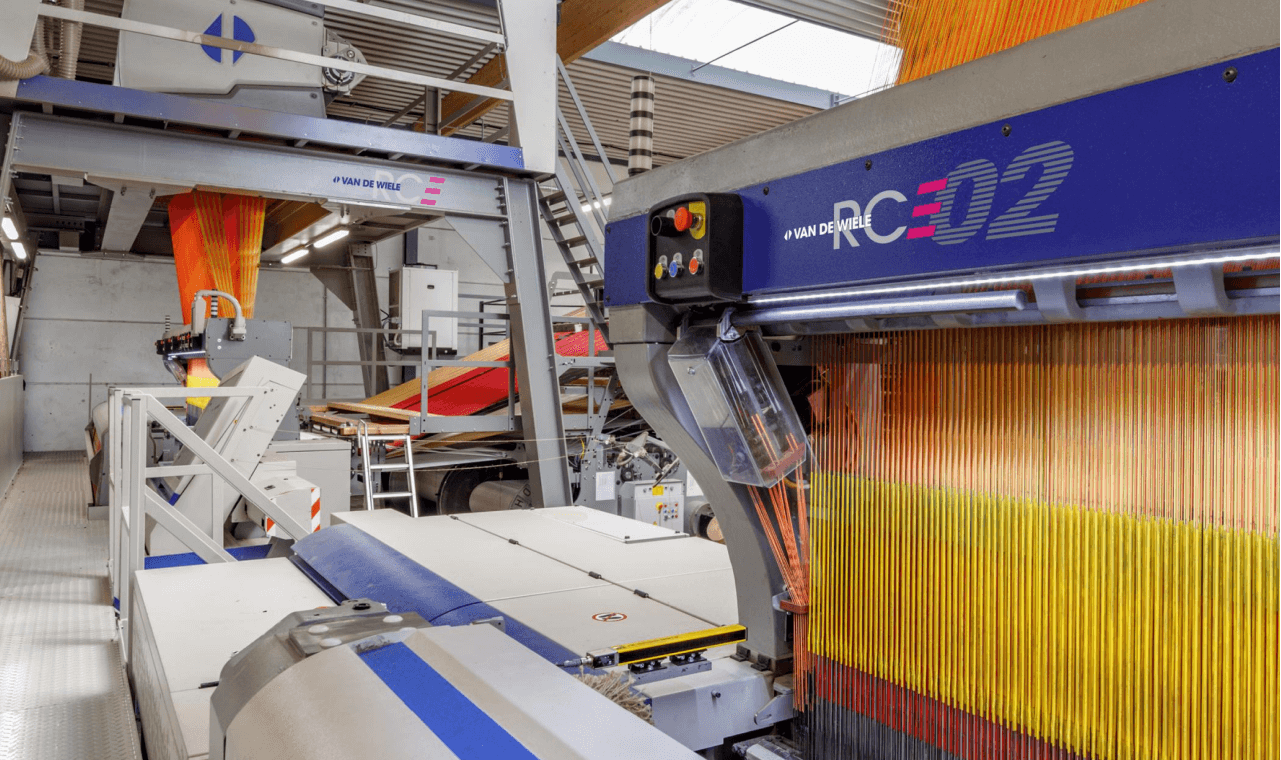

Vandewiele

Streamlining production planning and machine management in manufacturing

Rangel

Accessible medicine information for the masses with the help of blockchain

PerfectDraft. The perfect flow of beer and data thanks to the next generation of home draft systems.

AB InBev

PerfectDraft. The best connected home draft system pouring excellent beers and serving valuable data.

BIM e-Solutions

User-friendly ECTN platform for better cargo tracking

Corporify

A digital ledger that anyone can navigate and looks like a consumer app? Sounds like UX music to our designers’ ears.

Custo is more than a smart delivery box. It’s your personal assistant handling all that comes through your door.

Custo

Custo takes the smart delivery box to a higher level

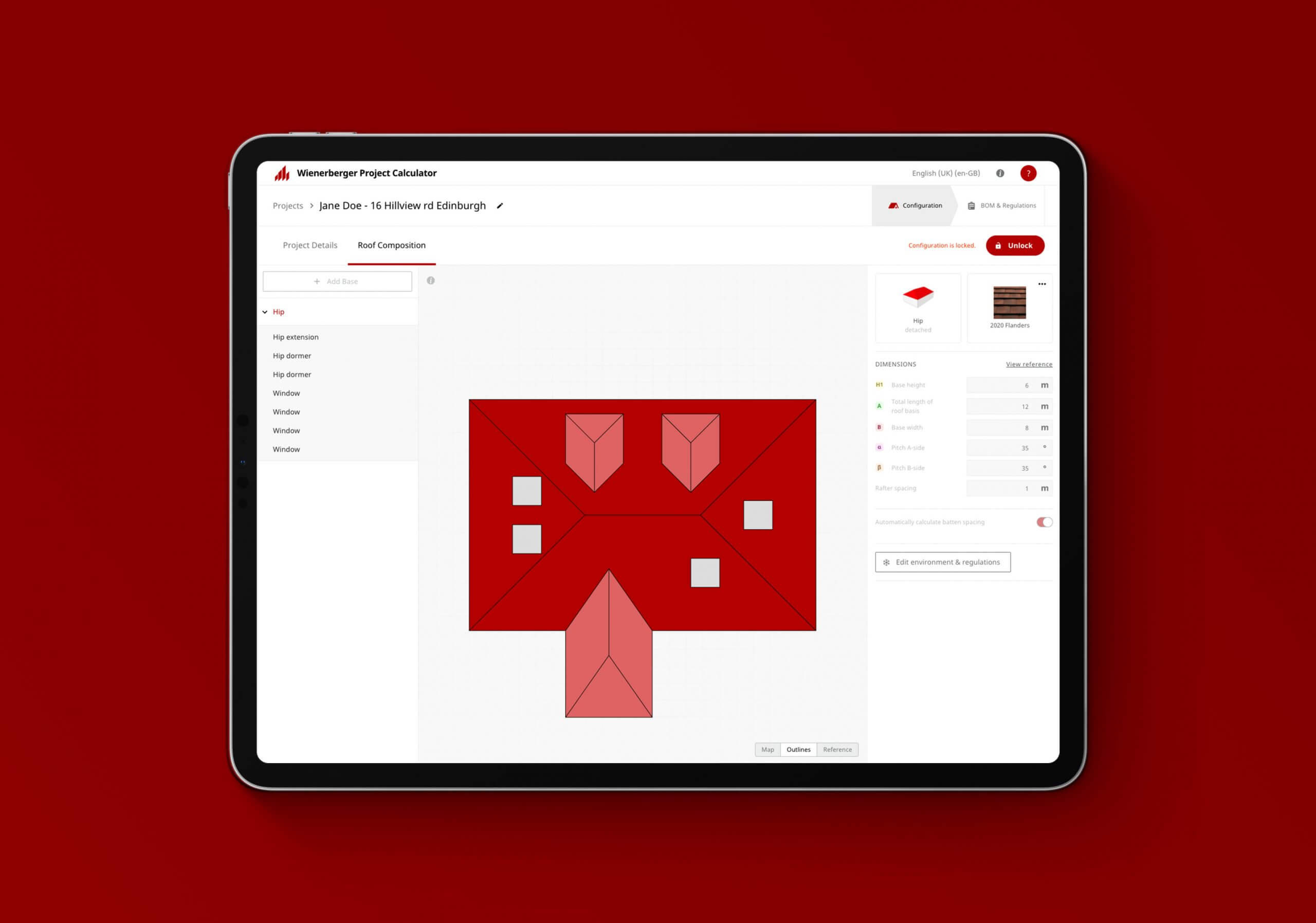

Wienerberger

Driving the digitalization of the construction industry

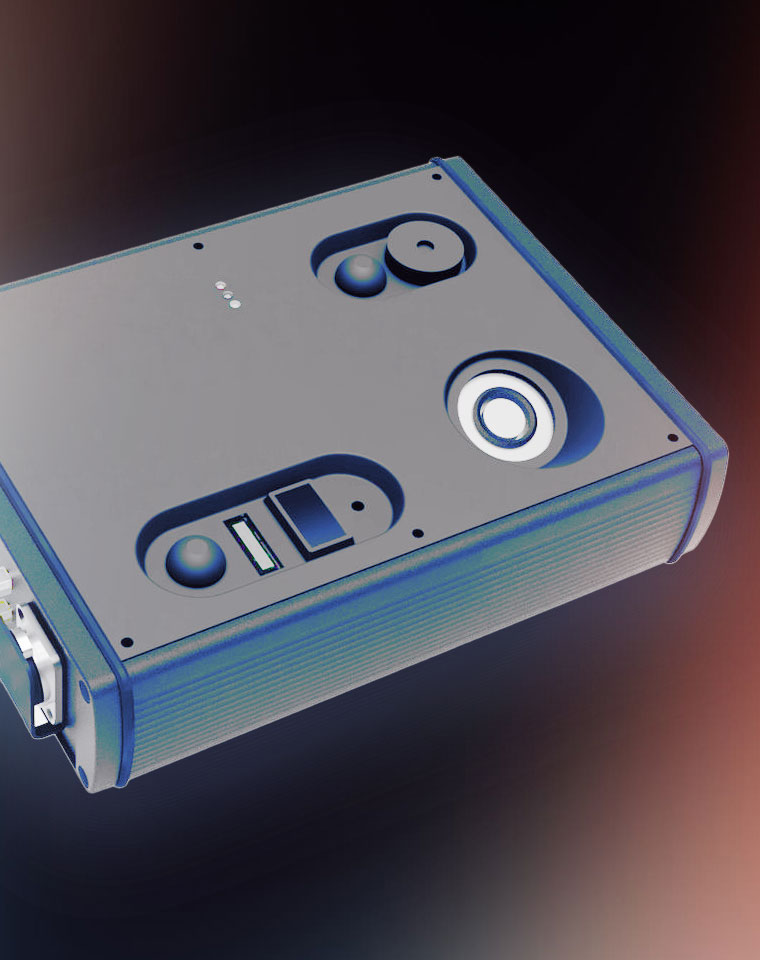

Improving safety in logistics with Ahlers. Together we developed an integrated and connected solution replacing Kalashnikovs.

Ahlers

IoT trackers to replace AK-47s

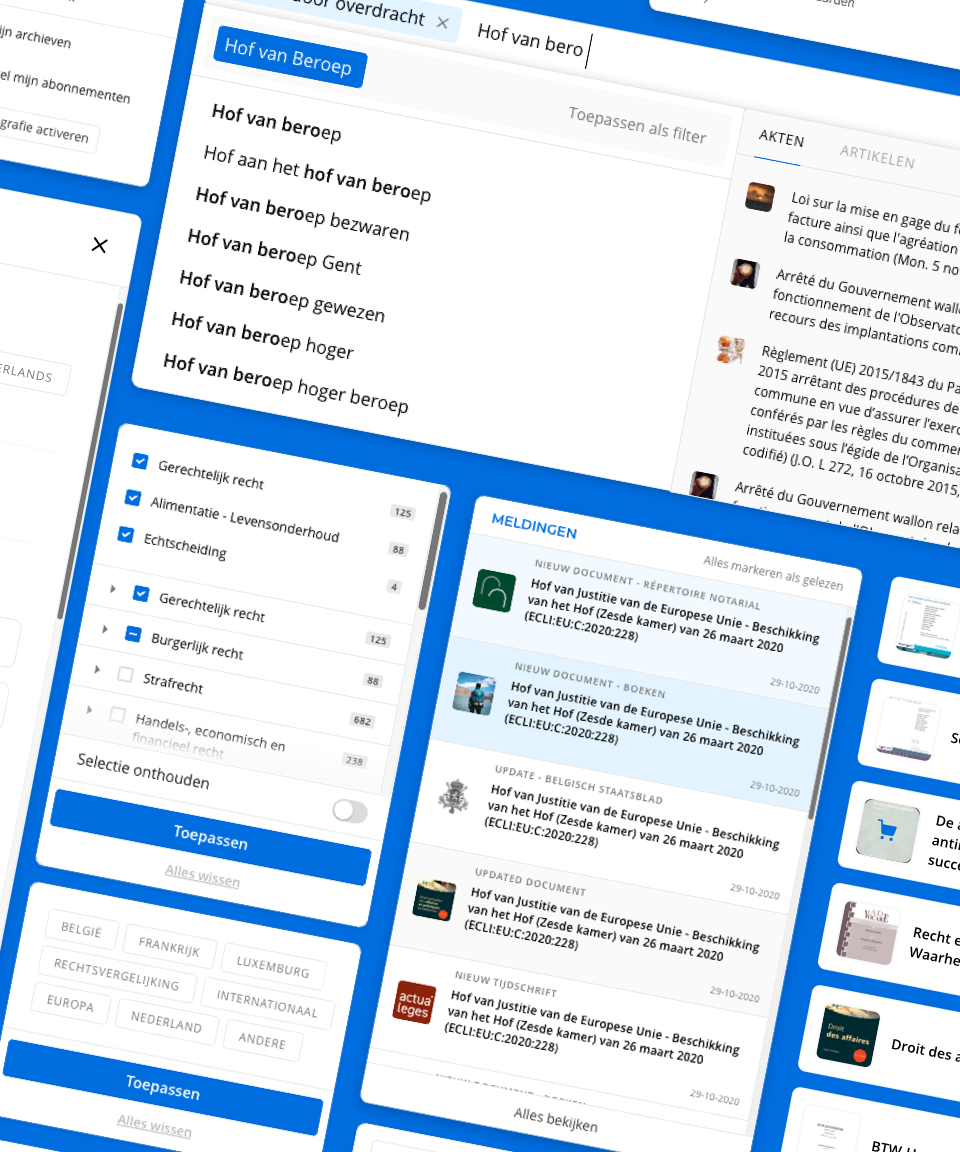

Strada lex

Navigating 2.5 million documents made easy

Find out how we helped a classic caterer flip their business model to smart fridges providing a wealth of insights.

Smart Fridge

Enabling catering-as-a-service with smart fridges

We helped OASE build a digital learning platform. Clients get access to thousands of bite sized videos or add their own to customize the experience.

OASE

A digital learning platform

A smart little IoT device that tailors your energy bill, June reduces the price you pay for energy by automatically changing energy suppliers.

June

Reducing your bills while you sleep

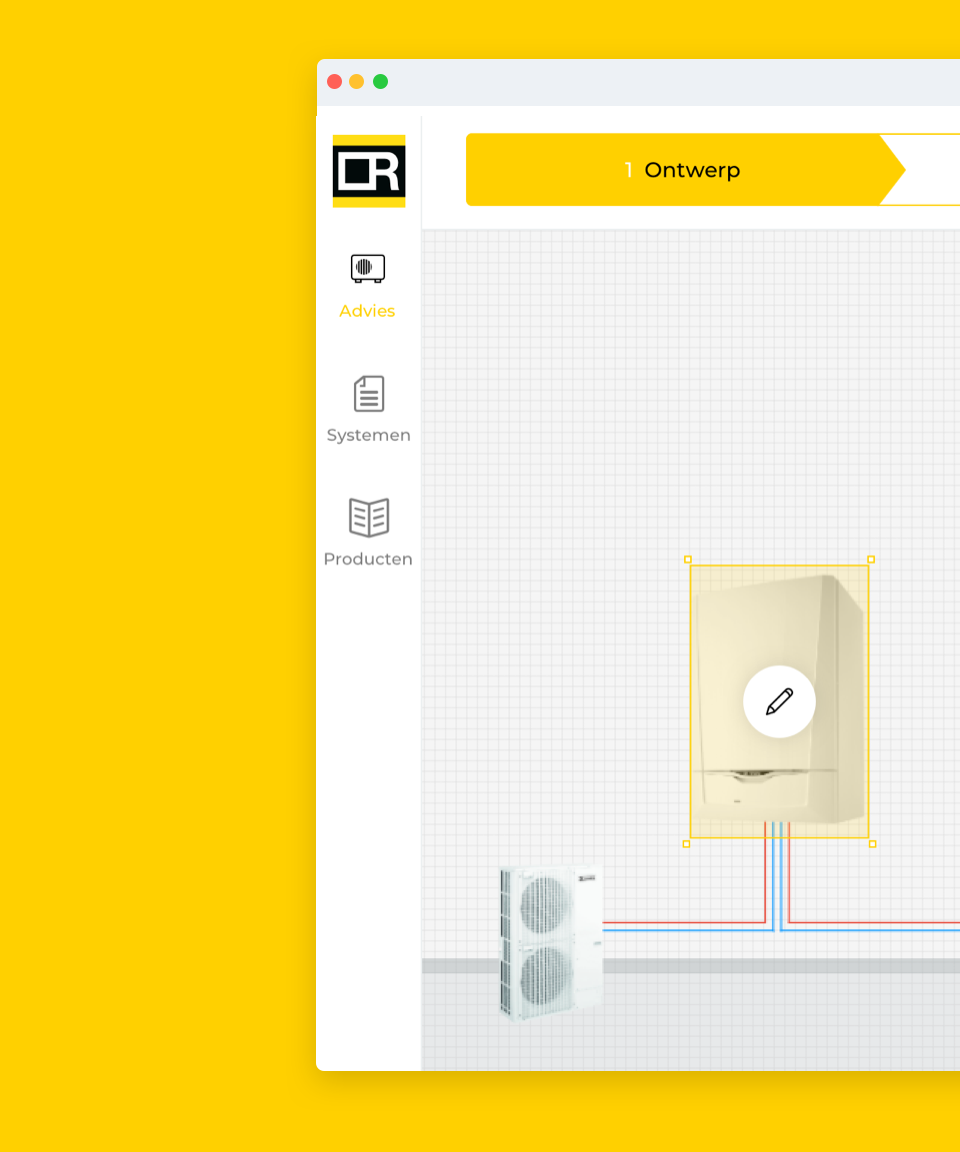

We helped heating expert Remeha explore the added value of digital, tailored to their specific needs and challenges.

Remeha

A digital system configurator

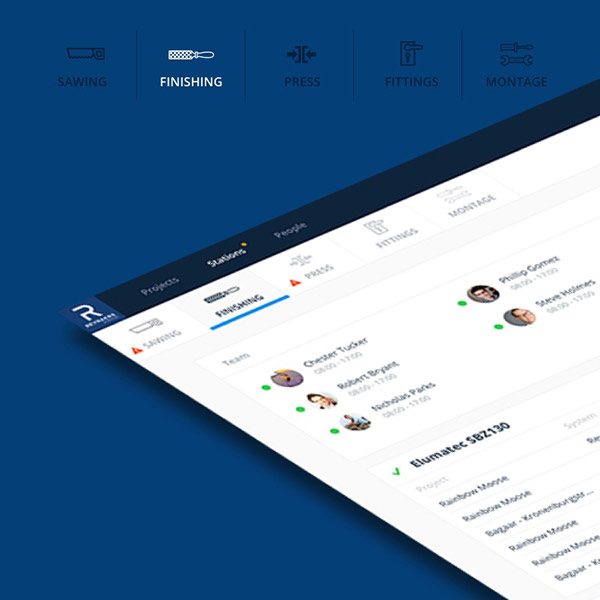

Devroye

Digital meets hardware with surgical precision

We collaborated with Barco to design their latest application Barco Synergi, working closely to develop an excellent user experience.

Barco Synergi

A tool for better meetings

Much more than a 3D textile configurator, we created a place of collaboration for sales, clients and their clients.

Bekaert Deslee

Building an innovation roadmap

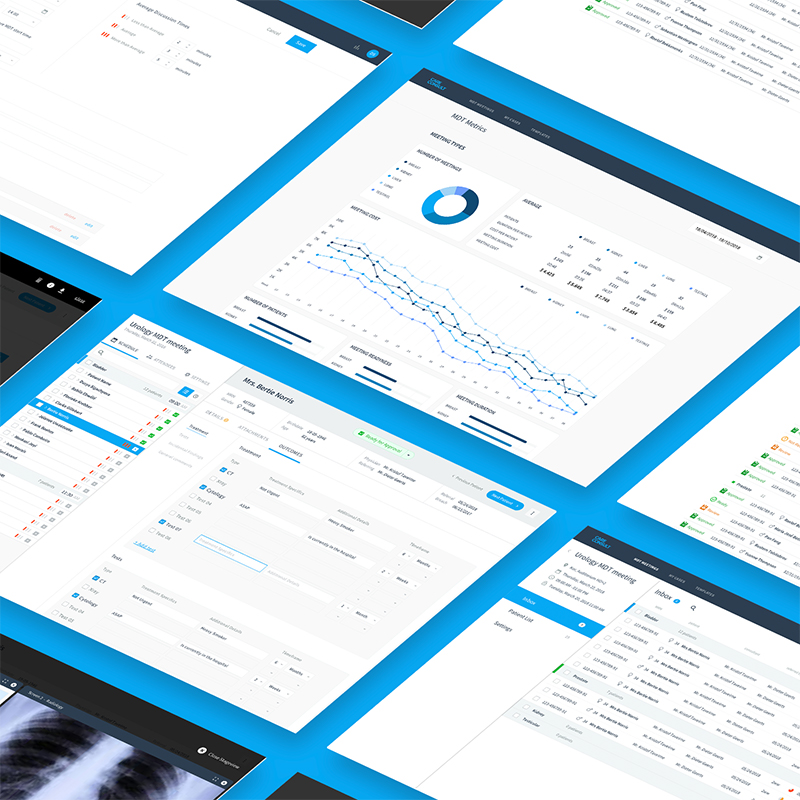

Discover how our UX solutions made life easier for installers, manufacturers, floor managers and operators. In short, everyone.

Reynaers Aluminium

The dashboard reinvented

Tell us everything!

We’d love to hear about your project and explore how we can help.